Plastic Actuated Butterfly Valves

Options - Series 92 Peaktronic Positioner

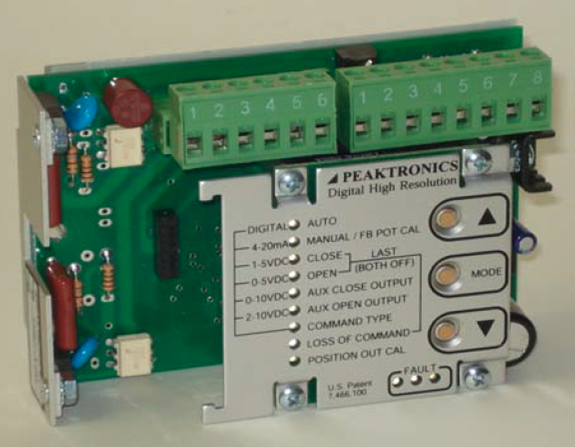

The DHC-200 positioner is a high performance, high resolution digital positioner. A simple three button control is used to configure ALL parameters that the unit needs for a variety of applications, and eliminates the need for special meters and/or tools for calibration. As long as there is supply power, the unit can easily be field calibrated

This positioner can be calibrated for various command types (such as 4-20mA, 1-5VDC, 0-5VDC, 0-10VDC, or digital) and also the default operation upon loss of command (such as fail open, fail close, or fail as is). The optional transmitter/auxiliary switch module is installed into the positioner card via plug and socket. This allows a user defined feedback signal of current or voltage, and provides 3-SPSt relay contacts for open position, closed position, and a fault condition.

New DHC postioner - Gen II

Please note: The new Gen II DHC positioner can be easily identified with three LED's located at the bottom of the positioner. The old style does not have any LED's.

Click here to get a copy of the OM Manual for the new positioner