Plastic Double Containment Piping Systems

Poly-Flo® PP-R and Advanced PE Co-extruded Double Containment Piping System

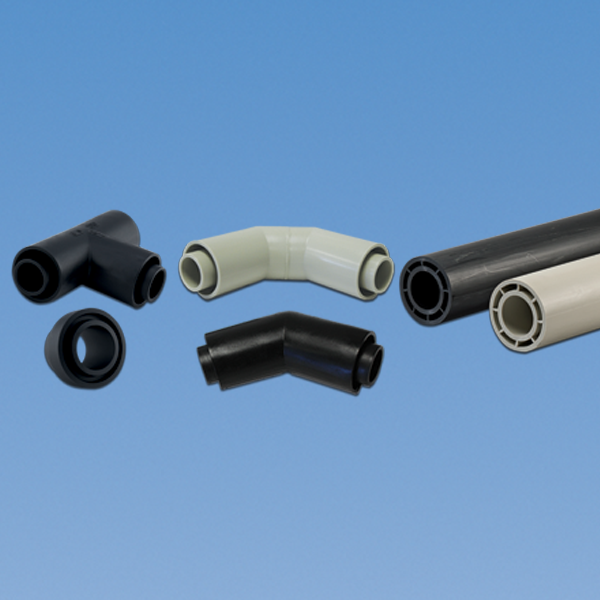

Asahi/America's Poly-Flo® PP-R and Advanced PE co-extruded double containment piping system offers time saving on each project. Low cost and easy installation makes Poly-Flo® the ideal system for drainage systems, pressurized transfer lines and industrial applications needing up to 4" carrier pipe.

Available in 1x1-1/2, 2x3, 4x6, and 6x9 size ranges, Poly-Flo® is designed for installations with tight space constraints, water treatment facilities using multiple chemicals and outdoor applications. In addition to pipe, the system includes full pressure fittings, drainage fittings, machined fittings and specialty dogbones for all standard size ranges.

Poly-Flo® is available in black PE and euro grey PP-R and operates to 150psi at 68 F. The co-extrusion allows Poly-Flo® to act like a single wall piping system by using fewer concerns during expansion and contraction and eliminates separation during directional drilling. The SDR design allows for full pressure rating while requiring no special welding clamps during joining. Poly-Flo® can be easily joined using standard welding equipment and does not require special inserts.

Resources

In the news

Data Sheet

Specifications

Asahi Minute Video