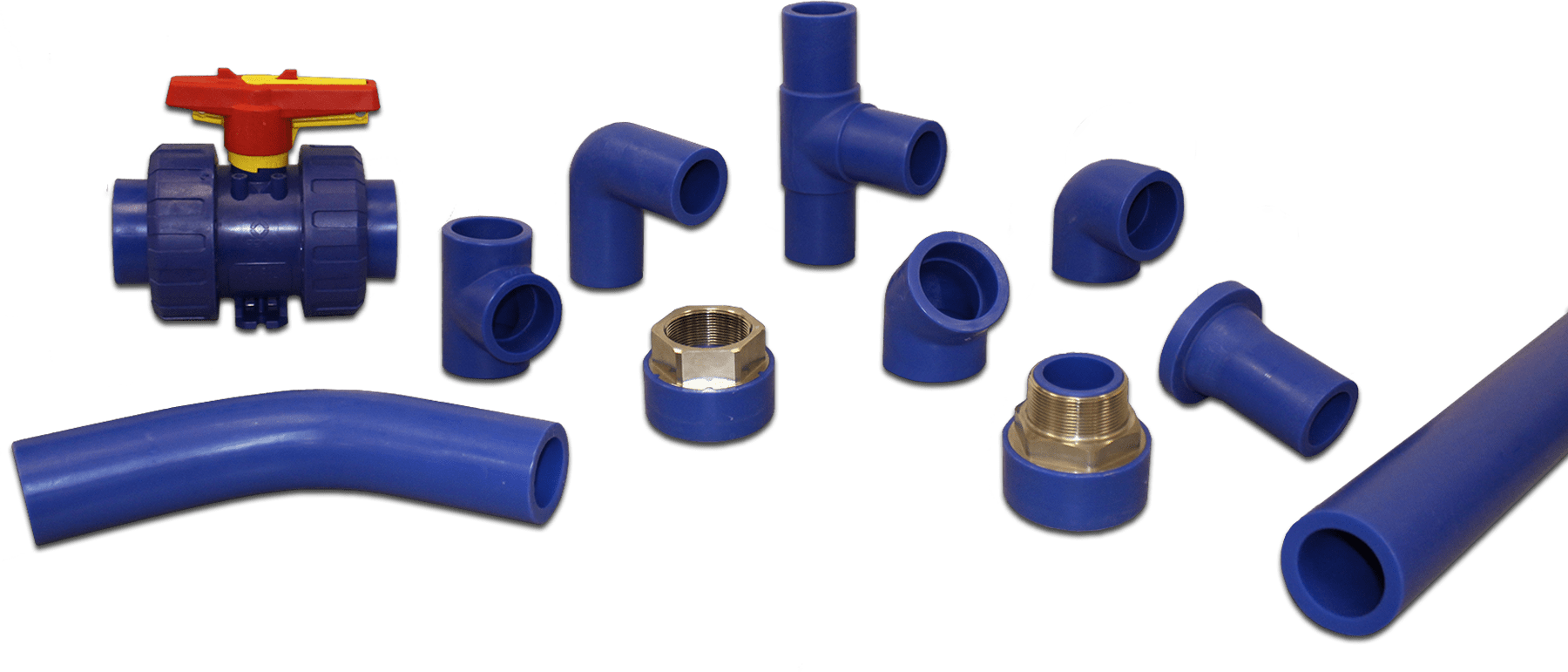

Industrial Piping

Air-Pro® Compressed Air Piping

Air-Pro® is the only PE piping system approved for use and warranted by the manufacturer for compressed air applications. Air-Pro® meets CAL-OSHA requirements for compressed air.

Air-Pro’s® specially formulated PE resins are resistant to both synthetic and mineral compressor oils.

Resources:

Catalog

Specifications

Ideal Applications Include:

Above and below ground compressed air, inert or non-reactive gases

Certifications/Warranty:

Supply Range:

Pipes & Pipe Fittings:

20 – 110mm (1/2″ – 4″) SDR 7.4 / 230psi

160 – 315mm (6″ – 12″) SDR 11 / 150psi

- Specifically designed for compressed air and gas service

- Excellent chemical and corrosion resistance

- Ideal for corrosive and marine environments

- Increased compressor efficiency due to low friction (Hazen & Williams C factor of 150)

- Easy installation via socket, butt and electro-fusion joining

- Thermal fusion is more reliable than metal welded, soldered, or mechanical joints

- High pressure capacity (rated for 230 PSIG @ 68° F and 100 PSIG @ 140° F)

- Lightweight materials reduce transportation costs

- Wide temperature range: 14° F – 140° F

- Resistant to all synthetic and mineral-based compressor lubricants including:

- Polyalpha-olefin (POA)

- Polyol-ester (POE)

- Diesters

- Meets Cal/OSHA requirements for safe transport of compressed air

- Suitable for above ground and direct-burial installations

- Designed for minimum expected useful life > 50 years up to 104° F

- Dimensional Guide – Air-Pro® Compressed Air Piping System

- Specification – Air-Pro® Compressed Air Piping System

- Submittal – Black Air-Pro® (6″ and higher) Submittal

Sales Resources

- Product Catalog – Air-Pro® Compressed Air Piping System | Spanish

- Air-Pro® Product Guide and Installation Manual

- Air-Pro® Application Documentation Sheet

- Case Study – Fertilizer Manufacturer

- Case Study – Shipyard

- Case Study – Airplane Manufacturing

- Case Study – Glass Manufacturing

- Case Study – Railroad Air Braking System