September 1, 2021

Inner Circle

Classifications, Certifications, Standards, and Codes: Marine and Oil and Gas Applications

The purpose of classifications, certifications, standards, or codes is to aid an industry and its regulatory bodies with regards to safety, based on a vast accumulation of their knowledge. Organizations worldwide define their activities by providing some form of classification services. At Asahi/America, we volunteer on several industry standards and code groups including, American Society of Mechanical Engineers (ASME), American Society for Testing and Materials (ASTM), American Welding Society (AWS), Plastic Pipe Institute (PPI), and Semiconductor Equipment and Materials International (SEMI). If you also volunteer on any of these or other groups, let us know how we can participate further and advocate for the safety of that industry.

In addition to those regulatory bodies, there are many more product and market standards that Asahi/America’s products meet so users can incorporate them confidently in a specific application. We will highlight two markets where classifications, standards, and codes are critical to the safety of operators, owners, and people nearby.

Marine environments, whether military or cruise ships, have classification standards that identify the requirements a product must meet in order to be installed. Asahi/America’s products meet requirements for certain areas of the ship under certain criteria. Additionally, we are currently advancing our product testing to reach new applications that solve corrosion problems for ship owners. According to The International Association of Classification Societies (IACS), “The objective of ship classification society is to verify the structural strength and integrity of essential parts of the ship’s hull and its appendages, and the reliability and function of the propulsion and steering systems, power generation and those other features and auxiliary systems which have been built into the ship in order to maintain essential services on board. Classification Societies aim to achieve this objective through the development and application of their own rules and by verifying compliance with international and or national statutory regulations on behalf of flag administrations.” In essence, it’s a way of saying industry standards are developed by industry experts and enforced by governing bodies.

Because ships have been a mode of transport for hundreds of years, there are multiple worldwide classifications, which have different criteria for uses. A summary of the major classification organizations, inception dates, and locations can be seen in the chart below. If the bureau has met certain criteria, they may be accepted by either the IACS or the European Maritime Safety Agency (EMSA). Both of those agencies have helped streamline international standardization efforts. There is often reciprocity among those groups of stakeholders.

Asahi/America’s marine product offerings easily solve some of the toughest corrosion challenges. Many applications, such as potable water, grey or bilge water, or wastewater could benefit from a non-corroding piping system when bombarded with non-stop salt water or salt air. An additional benefit of thermoplastic piping is a reduction in weight, which translates directly to operating cost reductions. The class requirements that our products meet are strenuous tests with restrictive testing requirements and constant maintenance. We are proud to achieve the following classifications for our products and encourage you to discover more about each of these products. Asahi/America products that meet the American Bureau of Shipping (ABS) classifications include, Type-21 ball valves, Type-57P butterfly valves, Series 92 electric actuators and Series 10 electric actuators. Products that meet Det Nirske Veritas (DNV) include, Series 79 pneumatic actuators made from Rilsan-coated aluminum, glass-filled polyamide, and 316 stainless steel. Our thermoplastic PP-RCT piping system Asahitec™ has the Lloyd’s Register and RINA Certification. Our Proline® piping system has the DNV and the Lloyd’s Register Certificate.

Are you designing process systems in this area? Let us know which classifications are important to you. Email us here.

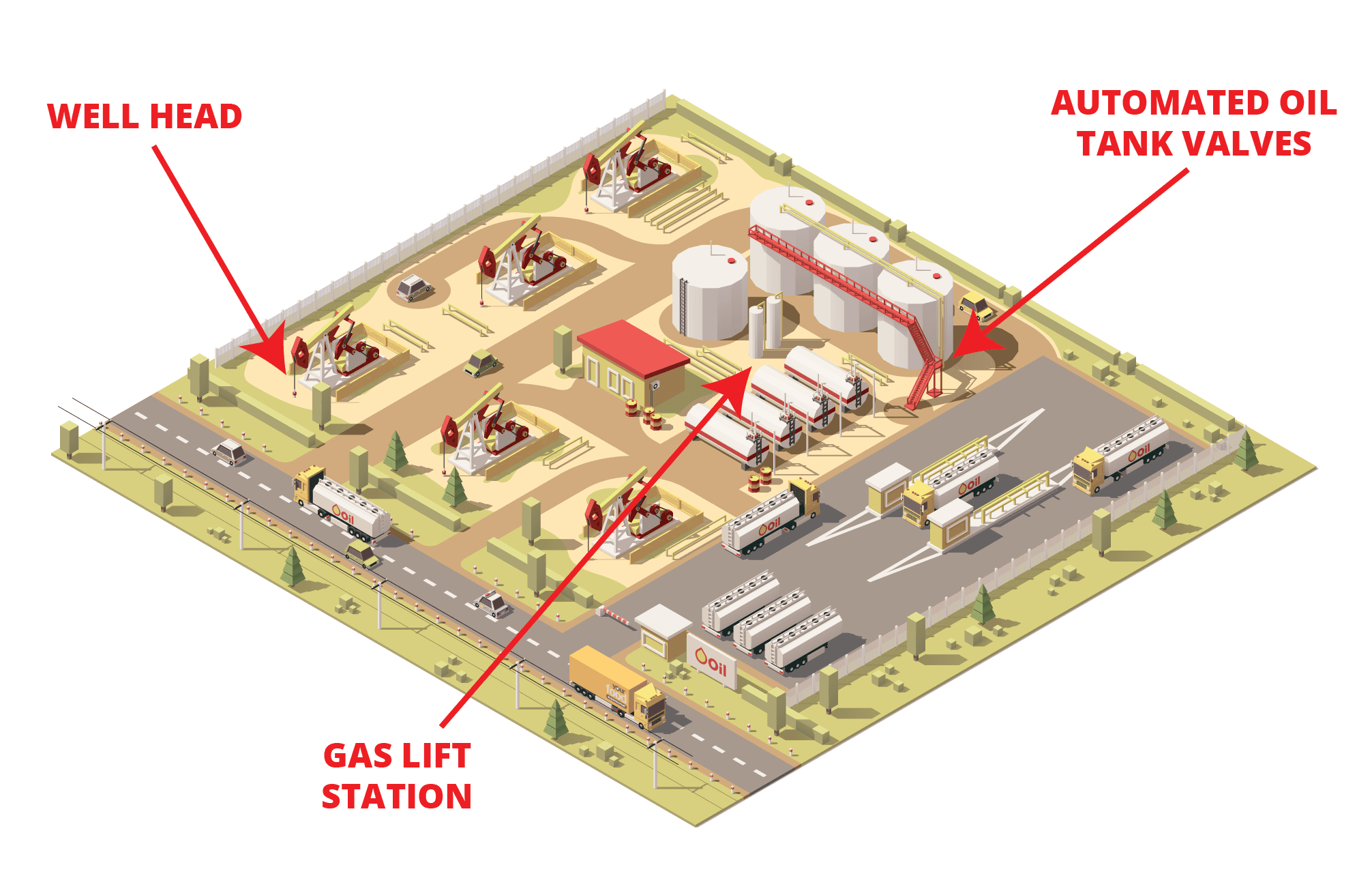

A similarly strict environment, which has hefty safety protocols and its own standards, is in the oil and gas field. Underwriters Laboratory (UL) 1203 provides categories for explosion-proof requirements. Asahi/America’s Series 92 electric actuator is regularly chosen in the oil and gas field because certain models have Class 1, Division 1 and 2 NEMA 7 explosion-proof enclosures. Applications where you might see our actuator in the oil field could be remote actuation of metal ball valves from oil storage tanks to tank trucks. Providing remote actuation also allows the driver to avoid harmful hydrogen sulfide fumes. You can also find Asahi’s actuation products at oil well gas lift stations, which provide control for the amount of gas for the gas lift operation and at the well head used on the valve to control the flow of the oil and gas. Luckily, we rely on third party requirements and testing, like UL, to ensure our product exceeds the requirements and the customer will not have to worry.

Did you know Asahi/America’s Series 92 electric actuator has:

- A UL 1203 Certified Class 1, Division 1&2 NEMA 7 explosion-proof enclosure

- An overload protection with automatic reset

- A permanently lubricated, solid gear that is Rockwell harden

An ISO mounting configuration

- A highly visible position indication

- A declutchable manual override

- A corrosion-resistant enclosure

- An extended duty cycles that are ideal for high cycling

Automated oil tank valves – Asahi/America’s Series 92 12VDC electric actuators are mounted on 2″ full port ball valves. The actuators are used to control the oil flow from the storage tanks to the oil tank trucks. This new automation system isolates the tank drivers from the harmful hydrogen sulfide fumes.

Gas lift station – A gas lift is a type of artificial lift used in oil wells. Compressed gas is injected back into the well to form bubbles in the tubing and lift-produced liquid rises to the surface. The gas is injected through a gas-lift valve either into the annulus between the casing and product tubing, or into the production tubing. The gas aerates the fluid in the tubing, reducing the weight and the aerated fluid flows up the tubing to the surface.

Well head – The Series 92 electric actuator is shown here operating a 2″ full port ball valve. The actuator receives a signal from a Remote Terminal Unit (RTU). The actuator is used on the valve to control the flow of the oil and gas. The oil goes to the storage tank and the gas is distributed to a separator.

Marine classification societies and UL safety organizations are a few of the many safety standard organizations that are necessary for every occupation. The common acceptance of standards is fundamental to the success of robust fair and free trade. They work to help create a safer, smarter, and a more secure and sustainable world.

EDITOR’S NOTICE: Please note, the information in this article is for educational purposes only and does not supersede any Asahi/America technical information or product specifications. Please consult Asahi/America’s technical department at 1-800-343-3618 or [email protected] on all product applications in regards to material selection based on the pressure, temperature, environmental factors, chemical, media, application, and more.