Gaskets & Backing Rings

AV Gaskets and Backing Rings

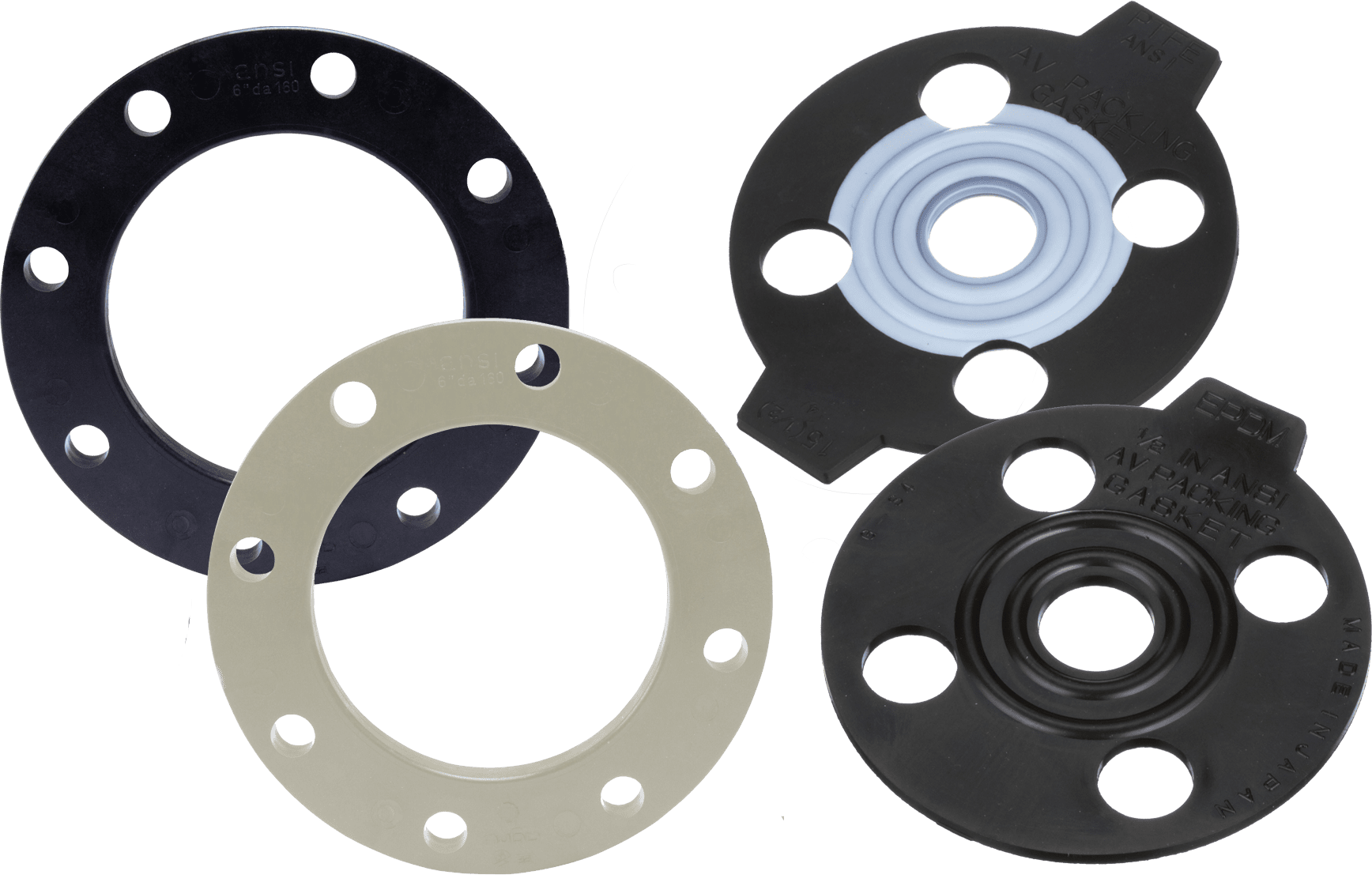

AV Gaskets (1/2″ – 12″)

Asahi valve gaskets offer a unique double convex ring design that gives optimum sealing with only 1/3 the torque commonly required with flat faced gaskets. Asahi/America offers EPDM gaskets from 1/2″ to 12″; PTFE-bonded EPDM gaskets in sizes from 1/2″ to 12″; and PVDF-bonded EPDM gaskets from 1/2″ to 10″.

AV low torque gaskets provide a bubble tight seal for flanged valve and piping connections. They feature a small bolt torque requirement for ease of installation and for accommodating a variety of thermoplastic valves, piping and fittings. All styles include two molded concentric sealing rings for confident sealing abilities. The sulfur-cured rubber is made to fit with flat faced flanges and is available with either a PVDF or PTFE laminated sealing surface for aggressive chemical or high purity installations.

Backing Rings (Euro Grey: 1/2″ – 12″; Black: 1/2″ – 24″)

Flange connections are an essential part of every piping system. For detachable connections to butterfly valves or transitions to other materials, Asahi/America’s backing rings, installed with plastic stub end flanges, are the ideal solution to provide a mechanical-locking connection offering superior safety for any system.

Resources:

Data Sheets

Specifications

Ideal Applications Include:

Chemical processing, bleach plants, aquariums, mining, water treatment, landfills, swimming pools, power plants

Specifications:

AV Gasket Sizes:

1/2″ – 12″

Materials:

EPDM, PVDF-bonded EPDM, PTFE-bonded EPDM

Bolt Patterns:

ANSI 150#

Backing Rings Sizes:

Euro Grey: 1/2″ – 12″

Black: 1/2″ – 24″

Materials:

PP with steel insert

Bolt Patterns:

ANSI 150#

JIS and DIN also available

AV Gaskets

- PTFE- or PVDF-bonded EPDM for maximum corrosion resistance and high fluid purity

- Perfect sealing at low bolt tightening torque ratings for longer gasket life

- Ideal for plastic piping systems, as well as metal or plastic-lined metal systems

- Sulfur cured

- Approximately 1/3 of the bolt tightening torque compared with flat or envelope type gasket

- PTFE-bonded gasket available for the most corrosive applications

- PVDF-bonded gasket ideal for the following:

- Semiconductor industry due to its purity

- Aggressive chemicals (strong acids, bases, halogens)

- Volatile media (fluids that generate gas): PVDF has a permeability of about 1/50th of PTFE

- Proprietary laminating process for bonding to EPDM that allows for the greater elasticity required for low torque gaskets

Backing Rings

- Fiberglass reinforced PP coated steel

- Available in UV resistant black or Euro grey PP

- Sized specifically for DIN metric piping

- Standard stock of ANSI 150# bolt pattern

- JIS and DIN patterns available