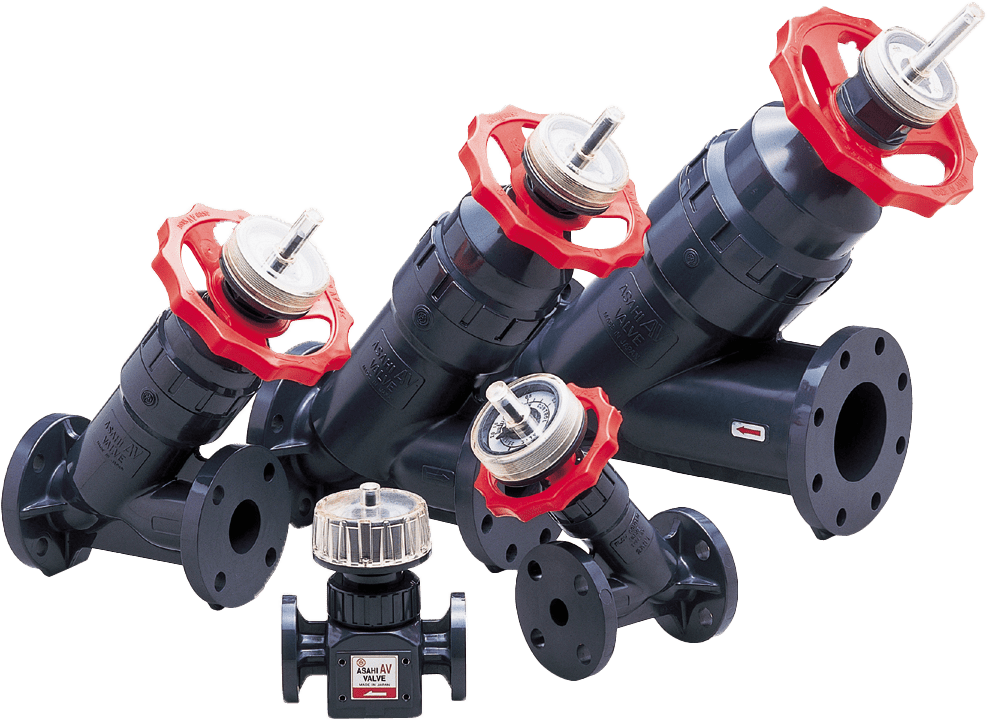

Thermoplastic Valves

Constant Flow Valves

Automatic flow control valve that can be manually set for different flow rates. The valve adapts to changing line pressure to maintain a steady flow rate in the downstream piping (see “Principles of Operation”) without automation (neither electricity nor an air supply is required). These are not recommended for use with viscous fluids, fluids with high specific gravities, or fluids that contain debris or suspended solids. Accurate to +/- 6% of desired flow rate, and can be adjusted without removing the valve from a line.

Resources:

Data Sheet

Specifications

Ideal Applications Include:

Chemical processing, aquariums, mining, water treatment, swimming pools, salt water, semiconductor

Specifications:

Sizes:

1/2″, 3/4″, 1″, 2″, 3″, 4″

Body:

PVC

Bonnet:

PVC

Models:

Flanged

Seals:

EPDM

Springs:

Stainless steel 304 with PCTFE coating

Temperature:

30 – 120º F

- Body and bonnet are of solid PVC

- All wetted parts are of thermoplastic and elastomeric materials for superior corrosion resistance

- A preset constant flow rate is maintained by automatically regulating orifice opening area, responding to changes of pressure differentials across the valve

- Vertical or horizontal installations

- Flow rate accuracy: +/- 6% of full scale flow rate (water at ambient temperature)

- Flow rate rangeability: 20:1 maximum

- Handwheel permits on/off opening and closing

- Handwheel serves as a mechanism by which the flow rate setting may be adjusted without shutting down the pipeline

- Springs of stainless steel 304 with PCTFE coating tested for long cycle life

- Prescribed flow setting is clearly visible on the indicator at the top